How important is a diverse portfolio of image sensors for smart factory robots?

Image sensors have always been key for machines and robots to recognise objects in factories and warehouses, and the ability to use 'what you see' to understand your environment has raised the bar for image sensor performance. It is important to realise that there is no single sensor solution for all applications. Therefore, a combination of different image sensors may be required. In this article, you will learn about the key performance metrics of the various image sensors needed to design a versatile autonomous mobile robot (AMR) or stationary robot.

1. Global shutter sensors for navigation and collision avoidance

Sensors in mobile phones use a "roll-up shutter" for image detection, exposing pixels sequentially, row by row. In this method, however, there is a slight delay between exposures for each row of pixels in the sensor, resulting in "artefacts" (visual anomalies) in the detected image, which are amplified by the angular motion and vibration experienced by the AMR as it travels through the shop floor. ONSEMI has developed an advanced image sensor with a "global shutter" that exposes all pixels at the same time to reduce the likelihood of artefacts in the image. This makes navigation of the AMR easier and reduces the possibility of collisions with other objects. Key metrics of the Global Shutter image sensor include:

1、Global shutter efficiency (GSE) quantifies a pixel's sensitivity to stray light contamination; sensors with a high GSE are less likely to produce images with smudges, specks, or artefacts.

2. Modular Transmission Frequency (MFT) is critical for image clarity. This is important in robots or machines that must be able to read bar codes. In addition, the ability to detect edges is a fundamental requirement for machines to use AI to understand their environment, and image sensors with high MFT enable this.

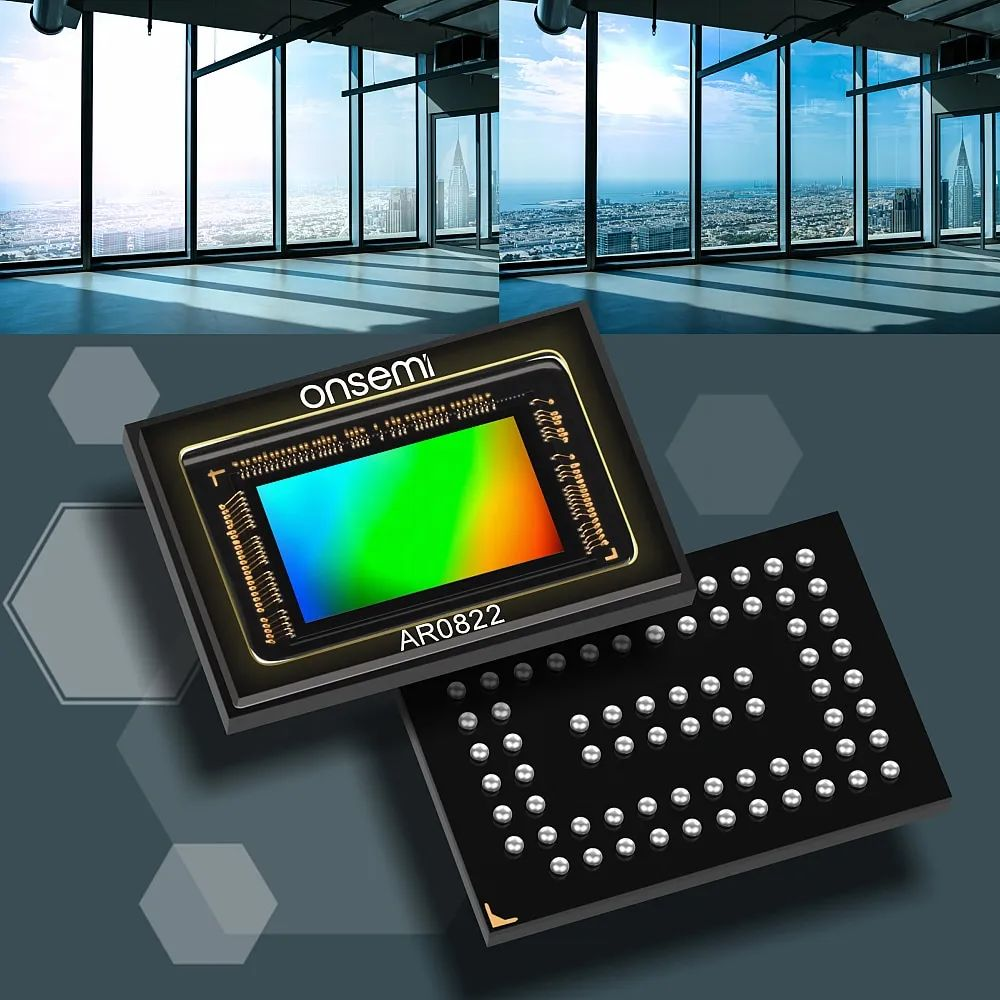

2、High Dynamic Range (HDR) for mixed lighting environments

Sensors with high dynamic ranges, from 100 dB to over 120 dB, can produce more detailed images under different lighting conditions, such as in factories or outdoor environments. HDR is provided through the use of multiple exposures and the recombination of long exposures (low light conditions), medium exposures (medium light conditions) and short exposures (high light conditions), but for higher resolution sensors, this approach significantly increases the frame rate, generates a large amount of data to be transferred to the AMR system-on-chip (SoC), and therefore increases power consumption and potentially contaminates the image data with noise. Using a different approach, ON Semiconductor offers the AR0822 8-megapixel sensor that reduces the SoC's data bandwidth by performing embedded image restructuring (eHDR). This approach also removes the burden of image processing from the SoC, allowing it to focus on AI or other tasks. In addition, the sensor features motion compensation to accurately capture fast-moving objects.

ON Semiconductor AR0822 with Embedded High Dynamic Range Example

03 High-resolution, large-format image sensor for range-finding applications and precise object placement Fixed robots sometimes need to read tags that contain information about the placement of objects. The distance between the sensor and the tag may vary from application to application, so high-resolution sensors capable of generating large-format images are required. ON Semiconductor's high-resolution sensors, ranging from 8 MP to 45 MP, are ideally suited for this application, enabling the robot to read the tag and accurately place the object at the intended destination.

04 ON Combines Sensor Expertise with Development Tools AMR and stationary robots perform a variety of tasks in the smart factory, so it's important to select image sensors that are optimised for specific automation tasks. Whether it's global shutter sensors for navigation and barcode reading, high-resolution sensors for long range and precise object placement, or HDR sensors for imaging in non-deterministic mixed-lighting environments, ON Semiconductor offers image sensors that provide AMRs and stationary robots with the right level of vision for their applications.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

- How TI’s investments in back-end manufac...

- Analog Devices Invests More Than $1 Bill...

- Analog Devices Releases 2022 Environment...

- IBM reinvents AI computing by using anal...

- Expert blog post Reducing Pin Usage in 8...

- Infineon's New Generation of Industrial ...

- How do I measure the light intensity of ...

- Microchip's New Cost-Effective Standalon...

- How important is a diverse portfolio of ...

- 【Application】Highly adaptable 20MHz acti...

.9246509.png)

service@weylan-d.com

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG